-

Menu -

Locations -

Search

John Deere 220 E-Cut™ Hybrid Walk Greens Mower

Double tap to zoom

220 E-Cut™ Hybrid Walk Greens Mower

Walk Greens Mowers

Overview:

- Easy reel maintenance

- Quick and easy troubleshooting

- Maximum comfort and control

- Quick release to disengage traction

Get A Quote

Fields with asterisks* are required. Please email our helpful staff with any questions or comments using the contact form.

Loan Calculator

Use the Loan Calculator to help you determine the financing and payment options that are best for you.

**The accuracy of this calculator and its applicability to your circumstances is not guaranteed. You should obtain personal advice from qualified professionals. This information is provided for illustrative purposes only and does not constitute an application. This notice does not guarantee loan approval, nor is it an offer or commitment to make a loan to you on the above terms.

Send To A Friend

Fields with asterisks* are required. Your friend will receive an email that contains a reference to this page. Please send this email only to people you know who would be interested in this information.

Share This Product:

Features

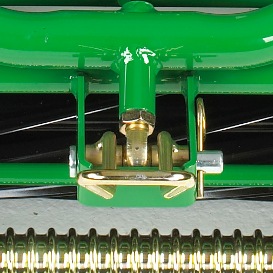

Ball-joint mounting system for contour following in all directions, even steering

Ball-joint mounting system

Ball-joint mounting system

The primary purpose of walk greens mowers with independent cutting units is to follow contours. It is in this area the 180 E-Cut™ and 220 E-Cut Hybrid Walk Greens Mowers truly excel.

Ball-joint mounting system

It all starts with the ball-joint mounting system that attaches the cutting unit to the traction drive system. Similar to the PrecisionCut™, E-Cut hybrid riding greens mowers, and fairway mowers with Quick-Adjust 5 (QA5) cutting units, the ball-mounting system allows the cutting unit to rotate in any direction.

The cutting unit not only moves fore and aft, and laterally side-to-side, it also steers in turns, which translates to a much more turf-friendly premium cut in cleanup passes around the perimeter of the green.

Due to the ball-joint design, and also the fact that the wiring harness is the only connection to the reel drive system, the cutting unit has virtually no mechanical linkage to restrict movement of the cutting unit in the toughest of undulations.

It is basically a one-gang triplex, and many are familiar with how well the PrecisionCut and E-Cut hybrid riding greens mowers follow contours, especially in the cleanup passes.

For maintenance, the reel can be removed by simply removing a pin, and the electric motor itself features a quick-attach design by simply loosening two 15-mm bolts, turning the motor slightly, and pulling the motor off of the cutting unit.

Cutting unit limit chains

Cutting unit limit chains

Control contour following

Limit chains on each side of the cutting unit control how much the cutting unit contours while mowing, while also controlling the amount of rear-roller drop when the unit is lifted for turns.

The initial setting of the chain is exactly the same as the 2500B PrecisionCut and 2500E E-Cut Hybrid Riding Greens Mowers. Two links should hang free, which means the chain itself is shortened to seven links. The upper chain anchor studs should be centered in their slots. This setting provides maximum contour following and maximum rear-roller drop when lifted.

However, the majority of greens will not require maximum contour following. Turning and maneuvering are easiest when the amount of contour following is limited to the requirements of the surface being mowed.

To limit the contour following of the cutting units, adjust the upper chain anchor studs backward in the slots to limit float and reduce the rear-roller drop. If further limitation is desired, shorten the chain to six links (three hanging free), and move the upper chain anchor studs forward in their slots.

Electric reel-drive system for excellent contour following and a premium quality of cut

Electric reel motor

Electric reel motor

Reel controller

Reel controller

The benefits of hybrid technology are numerous. The 2500E E-Cut™ Hybrid Riding Greens Mowers and E-Cut Hybrid fairway mowers are proof of that.

So why not move that same technology to the walk-behind greens mowers? With the 180 E-Cut and 220 E-Cut Hybrid Walk Greens Mowers, hybrid technology is now at your disposal on even the most undulating of greens.

In the case of walk greens mowers, hybrid technology provides more benefits than just noise reduction, fuel savings, and the elimination of any hydraulic leak points. With the 180 E-Cut and 220 E-Cut Hybrid Walk Greens Mower platform, the hybrid technology also allows a truly independent cutting unit that quickly reacts to contours, not only allowing the cutting unit to pivot laterally and fore-aft, but also to turn side to side for mowing cleanup passes.

Because of the hybrid technology in the 180 E-Cut and 220 E-Cut Hybrid, the only link between the cutting unit and the traction unit for turning the reels off and on is the wiring harness. The wiring harness can easily move in any direction the cutting unit needs to go. There are no hard linkages in the reel-drive system to limit the cutting unit's ability to follow contours.

In addition, the electric drive system makes it easy to backlap by simply flipping a switch. No need for a special backlapping tool to spin the reel in reverse. It is all on board the 180 E-Cut and 220 E-Cut Hybrid as base equipment.

Frequency of clip is also adjustable by a dial behind the handlebar cover.

The system is powered by a Honda® engine, which turns an electric motor that is used as a generator. In between this motor and the electric reel-drive motor is the reel controller itself.

Similar to the controllers used on the 2500E E-Cut Hybrid Greens Mowers and E-Cut Hybrid fairway mowers, the controller takes the power from the generator and controls the reel speed. This particular controller monitors engine rpm and controls reel speed to precisely match the frequency of clip that has been set.

The electric reel-drive motor itself is the same one used on the 2500E E-Cut Hybrid Riding Greens Mowers and E-Cut fairway mowers – proven technology with proven results.

Honda is a U.S.-registered trademark of Honda Motor Company.

Adjustable frequency of clip to meet turf conditions

Frequency of clip dial

Frequency of clip dial

The buzz in the industry is all about frequency of clip. But what exactly is it? Frequency of clip is defined as the distance traveled between consecutive cuts. In other words, it is how far the machine moves from the time one blade passes across the bedknife until the next blade passes. The lower the frequency of clip, the less distance that is traveled until the next blade passes.

Some will say that the lower the frequency of clip the better the cut quality, but that is a misconception as the key factors of cut quality are the following:

- Geometry of the cutting unit

- Sharpness of reels and bedknife

- Proper cutting unit set up (parallel and bedknife to reel)

- Height of cut

- Bedknife selection

- Roller selection for the turf conditions

- Turf conditions

There is a point of diminishing returns when it comes to frequency of clip. The less distance the mower travels between consecutive cuts, the more times the same grass blade is going to be impacted by the reel, which leads to bruising of the turf – especially in the overlap from pass to pass.

Optimum frequency of clip

So, what is the optimum frequency of clip? It all depends on conditions. And the 180 E-Cut™ and 220 E-Cut Hybrid Walk Greens Mowers give the ability to establish a frequency of clip that is appropriate for individual conditions.

The adjustment is a rotary dial located behind the handlebars. The system comes with a standard locking cover that must be accessed with tools, ensuring only those trusted to make this change, such as the superintendent or technician, can do so.

Once the frequency of clip is established, the 180 E-Cut and 220 E-Cut Hybrid Walk Greens Mowers mow at that frequency of clip, no matter the traction speed of the machine.

It does this by monitoring the engine rpm. As the throttle is decreased, the controller slows down the reel motor to match the new speed of the traction system, maintaining a constant frequency of clip. As the throttle is increased, the controller speeds up the reel motor to maintain the frequency of clip.

Similar to the SL Series Walk Greens Mowers, this system keeps frequency of clip the same from operator to operator. This means no cut quality difference between more experienced operators mowing at a faster ground speed and less experienced operators mowing at a slower ground speed.

Standard onboard backlapping for easy reel maintenance

Backlapping switch

Backlapping switch

A significant benefit to the electric reel-drive system is that it is very simple to change the direction of the motor, which allows the cutting unit to spin either forward for mowing or backward for backlapping.

The 180 E-Cut™ and 220 E-Cut Hybrid Walk Greens Mowers can be backlapped without needing any external devices to drive the reel backward. It can do it all by itself with a simple toggle switch located on the rear left-hand side of the machine.

To backlap, simply set the park brake, start the engine, toggle the mow or backlap switch to backlap, and turn on the power take-off (PTO) by toggling the PTO rocker switch on the front of the handlebar cover. The reel controller automatically sets the optimum backlapping speed; no special tools or rotary dials are needed to adjust the speed.

This onboard backlapping saves a lot of time and money, while keeping reels in top shape for a premium quality of cut.

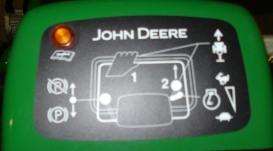

Standard diagnostic light for quick and easy troubleshooting

Diagnostic light

Diagnostic light

Service ADVISOR™ location

Service ADVISOR™ location

For quick and easy troubleshooting should an issue arise, a diagnostic light is located on top of the handlebar cover. If the electrical system sees a problem, a diagnostic code flashes through the indicator light. The code is repeated until the power take-off (PTO) switch is cycled off and on again, or the engine is shut off and turned on again.

When a code is discovered, consult the technical manual for additional troubleshooting information. If a continuing condition exists, the diagnostic code displays again when the engine is started, until the original condition is corrected.

The controller is also configured to store any code that has been displayed, so dealers can see a detailed history of the unit to aid in additional troubleshooting. The information is accessible by dealer technicians only using Service ADVISOR.

Grass-catcher system — fixed to the plane of the reel for maximum performance in severe undulations

Grass-catcher

Grass-catcher

The direct-mounting grass catcher is designed to retain clippings by slowing down the air volume and routing it out of the catcher while keeping the clippings in. Molded-in grooves and mounting brackets make it easy to remove and replace the catcher. The catcher is made of lightweight polyethylene material that resists corrosion and cracking, reduces vibration, and is easy to use.

Overlap marks for lining up to previous pass are molded into the top of the catcher for increased productivity and straightly mowed passes.

The direct-mounting design grass-catcher system is fixed to the same plane as the reel. This means the grass catcher follows contours exactly as the reel does, maximizing the volume of grass thrown into the catcher. It also increases operator productivity by the easy removal and installation of the grass catcher.

Dual traction rolls for straight tracking and excellent maneuverability

Traction drum

Traction drum

The dual traction rolls for the rear drum are powered by an external differential drive. This design provides equal power to both rolls for the straightest possible tracking. The external differential drive and split drum work together to allow minimal turning efforts and excellent maneuverability when making turns and mowing cleanup passes.

The traction-drive rolls are constructed of aluminum, which offers corrosion resistance for durability and a long life. The smooth roller surface on the 180 E-Cut™ and 220 E-Cut Hybrid Walk Greens Mowers provide an evenly-rolled appearance on greens and other mowing surfaces.

The outside ends of the traction rolls are tapered to provide a smooth transition between the rolled and non-rolled surface areas.

Quick-Adjust 5 (QA5) 14-blade cutting unit lowers frequency of clip (FOC)

14-blade reel

14-blade reel

Using the QA5 14-blade cutting unit option on Greens Mowers will lower the FOC and also provide a clean, smooth cut. It can increase the playability of the putting surface and greens speed.

FOC is defined as the distance traveled between consecutive cuts. It is how far the machine moves from the time one blade passes across the bedknife until the next blade passes. The lower the FOC, the less distance that is traveled until the next blade passes.

There is a point of diminishing returns when it comes to FOC. The less distance the mower travels between consecutive cuts, the more times the same grass blade is going to be impacted by the reel. Too low an FOC can cause bruising of the turf — especially in the overlap from pass to pass.

FOC is often used as a measurement of cut quality; however, there are other key factors that attribute to gaining superior quality of cut that are more critical than FOC. The factors that lead to good cut quality are:

- Geometry of the cutting unit

- Sharpness of reels and bedknife

- Proper cutting-unit setup (parallel and bedknife-to-reel clearance)

- Height of cut (HOC) (effective versus bench HOC)

- Bedknife selection

- Roller selection for the turf conditions

- Turf conditions

The geometry of John Deere cutting units makes the optimum range for FOC between 0.160 in. (4.064 mm) and 0.190 in. (4.824 mm) for Walk Greens Mowers and 0.044 in. (1.1176 mm) per 1 mph (1.6 km/h) for Riding Greens Mowers. Technology of the QA5 cutting units excel and provide a superior cut and after-cut appearance.

Machines |

Minimum FOC |

180 E-Cut™ Walk Greens Mower |

0.125 (3.18) |

220 E-Cut Walk Greens Mower |

0.125 (3.18) |

2500B PrecisionCut™ Riding Greens Mower and 2500E E-Cut Riding Greens Mower |

0.034 (0.86) per 1 mph (1.6 km/h) |

Larger, 63.5-mm (2.5-in.) front grooved disc roller compatible with fairway tender conditioner (FTC) and Greens Tender™ conditioner attachment for 55.9-cm (22-in.) Quick-Adjust 5 (QA5) reel cutting units

Grooved disc roller

Grooved disc roller

The grooved disc roller can be used with 55.9-cm (22-in.) QA5 cutting units, in combination with the Greens Tender Conditioner and FTC, to provide additional roller options for fairway, tees, and approach areas.

The increased diameter improves the durability over smaller rollers, and it features hardened discs for improved wear which retains spring tension for reduced maintenance, making it an ideal roller for fairway, tee, and approach mowing.

Specifications

Key Specs

| Engine Type | Air-cooled, Gas |

|---|---|

| Horsepower | At 3600 rpm: 2.4 kW 3.2 hp Engine manufacturer net power, tested in accordance with SAE J1349. The engine horsepower and torque information are provided by the engine manufacturer to be used for comparison purposes only. Actual operating horsepower and torque will be less. Refer to the engine manufacturer’s website for additional information. |

| Cutting width | 55.9 cm 22 in. |

| Reel diameter | 127 mm 5 in. |

| Number of blades | 7, 11 or 14 blade |

| Frequency of clip standard | Variable with 5 settings 11 Blade 4.1, 4.6, 5.6, 9.7, 12.2; 14 Blade 3.2, 3.6, 4.4, 7.6, 9.6 mm Variable with 5 settings 11 Blade 0.162, 0.180, 0.220, 0.380, 0.480; 14 Blade 0.120, 0.140, 0.180, 0.300, 0.380 in. |

| Traction drum | Dual, aluminum |

| Forward speed | With transport wheels at 3000 engine rpm: 7.2 km/h km/h 4.5 mph |

| Weight (less GTCs, gear drive and transport wheel with catcher) | 119 kg 262 lb |

| Operator ear | 79 dBA |

Engine

| Type | Air-cooled, Gas |

|---|---|

| Cycle | 4-cycle |

| Bore and stroke | 60x42 mm 2.36x1.65 in. |

| Piston displacement | 122 cc 7.4 cu in. |

| Compression ratio | 8.5:1 |

| Horsepower | At 3600 rpm: 2.4 kW 3.2 hp Engine manufacturer net power, tested in accordance with SAE J1349. The engine horsepower and torque information are provided by the engine manufacturer to be used for comparison purposes only. Actual operating horsepower and torque will be less. Refer to the engine manufacturer’s website for additional information. |

| Direction of rotation of output shaft | Counterclockwise viewed from shaft side |

| Inclination limit | Tilted up to 20 degrees in any direction |

| Idle speed at output shaft | 1700 (+/- 100) rpm |

| Maximum speed at output shaft | 2950 (+/-150) rpm |

Fuel

| Type | Regular grade unleaded or leaded |

|---|---|

| Tank capacity | 2.5 L 0.66 U.S. gal. |

Oil

| Type | SAE 30 or SAE 10W-30 |

|---|---|

| Capacity | 0.6 L 0.63 U.S. qt |

| Differential drive capacity | 0.14 pt 0.3 L |

Cutting equipment

| Cutting width | 55.9 cm 22 in. |

|---|---|

| Cutting height (minimum) | Standard - 3.0-mm bedknife Min. 3.2 mm 0.125 in. Max: 22 mm 0.875 in. option Optional - 2.5-mm bedknife Min 2.5 mm 0.098 in. Max. 22 mm 0.875 in. option Optional - 2.0-mm bedknife Min 2.0 mm 0.078 in. Max. 22 mm 0.875 in. standard |

| Frequency of clip standard | Variable with 5 settings 11 Blade 4.1, 4.6, 5.6, 9.7, 12.2; 14 Blade 3.2, 3.6, 4.4, 7.6, 9.6 mm Variable with 5 settings 11 Blade 0.162, 0.180, 0.220, 0.380, 0.480; 14 Blade 0.120, 0.140, 0.180, 0.300, 0.380 in. |

Reel

| Diameter | 127 mm 5 in. |

|---|---|

| Number of blades | 7, 11 or 14 blade |

| Material | Heat-treated chromium molybdenum steel |

| Bedknife - standard |

Optional rotary brush and Greens Tender™ Conditioner (GTC)

| Brush | Interlocked with reel, rotation in reverse direction; nylon diameter: 60 mm 2.375 in. |

|---|---|

| GTC cutter blades | |

| Adjustable brush or cutter height | Brush even with height-of-cut; GTC below height-of-cut maximum: 0.8 mm 0.031 in. |

| Gear drive |

Grass catcher

| Size, lb (kg) | 3.2 kg 7 lb |

|---|---|

| Type | Polyethylene |

Clutches

| Transport | Belt tension |

|---|---|

| Reel jaw-type clutch | On/off |

| Brush/GTC jaw-type clutch | On/off |

| Traction drum | Dual, aluminum |

Traveling device

| Forward speed | With transport wheels at 3000 engine rpm: 7.2 km/h 4.5 mph |

|---|---|

| Roller - rear | Aluminum, diameter: 190 mm 7.5 in. |

| Roller - front (grooved or smooth) | Machined steel, diameter: 50 mm 2 in. for cutting height adjustment) |

Dimensions

| Length (with tires installed) | 99 cm 39 in. |

|---|---|

| Width (with tires installed) | 94.6 cm 37.25 in. |

| Height (with tires installed) | 119 cm 47 in. |

| Weight (less GTCs, gear drive and transport wheel with catcher) | 119 kg 262 lb |

Certificate

| Type | ANSI B71.4-2004 |

|---|

Sound levels

| Operator ear | 79 dBA |

|---|---|

| Measuring standard | ISO 11201 |

| Attachments installed | GTCs, reels engaged |

Additional information

| Date collected |

|---|

Contact Us

-

325 Walt Messick Road

Harrington, Delaware 19952

Phone: (302) 398-3729

Toll Free: (800) 237-1272