Features

Stamped rotary decks and rigid frame construction to maximize deck durability

9009A TerrainCut™ Rough Mower

9009A TerrainCut™ Rough Mower

7400A TerrainCut Trim and Surrounds Mower

7400A TerrainCut Trim and Surrounds Mower

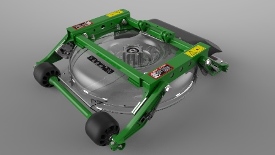

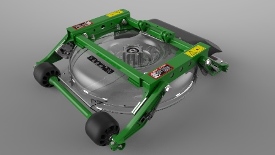

The 9009A TerrainCut Rough Mower is equipped with five and the 7400A TerrainCut Trim and Surrounds mower is equipped with three 68.6-cm (27-in.) stamped rotary decks for superior productivity and strength. The rotary decks perform exceptionally well across a wide range of grass types, including warm- and cool-season grasses.

Stamped deck shell

Stamped deck shell

A strong stamped, 10-gauge shell construction is an integral part of this durable deck. The stamped design uses a single piece of steel to form the shell that provides consistent strength throughout all areas of the deck. This is the starting point of the strength and durability of the deck construction.

Frame support and protection

Frame support and protection

Surrounding the deck is a tough, steel frame designed to protect the deck shell. It all starts with the frame on top of the deck which is then bolted to the shell providing extra protection. The front and rear roller brackets are attached to the framework, so as the front and rear rollers encounter obstacles, the force is transferred through the frame rather than through the deck shell. This design also decreases the distance from the blade tip to outside edge of the deck for closer trimming around objects like trees and fences.

Angled skid plate

Angled skid plate

An angled skid plate between the front roller and deck shell helps protect the front lip of the deck from tough terrain such as tree roots or other objects. The skid plate helps move the deck over the object to prevent the front edge from contacting and damaging the deck shell. The side of the deck also has additional protection to increase durability with a 38-mm (1.5-in.) tall and 12.7-mm (0.5-in.) thick steel stock welded to the decks edge.

Roller brackets are cast steel with extended housings to effectively protect the roller bearings from a wide range of debris types. The large front rollers are greaseable to help purge water and debris and use snap rings to ensure bearings stay in place, increasing durability and longevity of the front rollers.

Rear-discharge design provides premium cut quality and dispersal for less clumping and blowing for cleanup

68.6-cm (27-in.) deck and frame

68.6-cm (27-in.) deck and frame

Asymmetric rear discharge

Asymmetric rear discharge

The 9009A and 7400A TerrainCut™ Mowers 68.6-cm (27-in.) deck features a deck design with an asymmetric rear discharge cutout and molded chute to promote better airflow, leading to improved clipping dispersal and cut quality.

The unique shape of the deck shell cutout includes a heavily rounded opening on one side that gradually transitions to a larger opening on the other side of the cutout, allowing the grass to exit the deck evenly while significantly reducing the possibility of the deck congestion. This design incorporates deck structure along the bottom of the discharge area that reduces sound power, does not affect cut quality negatively, and acts as a foot guard eliminating the need for an external guard that can lead to external grass build up which can be dropped in the mowing pass over time.

When the asymmetric deck shell discharge shape is used in combination with the asymmetric discharge chute, this deck outperforms the competition in cut quality by minimizing clumping with smooth transitions and guiding the discharge material in a more dispersed pattern.

The improved dispersal will lead to less clean up and blowing, allowing machines to mow earlier in the day while saving time and reducing labor.

The proper blade selection for heights of grass, grass type, and sharp blades are keys to improved cut quality and dispersal. The removal of no more than one third of the grass blade is recommended. During heavy growth times it may require changing blades, mowing more often or raising the height of cut to improve clipping dispersal.

eHydro™ hydrostatic pump and large-capacity wheel motors for serious hill-climbing capabilities and lower maintenance

Large wheel motors

Large wheel motors

eHydro traction pump

eHydro traction pump

The 9009A TerrainCut and the 8900A PrecisionCut utilizes the same eHydro traction pump and wheel motors in the A-model take performance, traction, and operation to the next level. This is combined with the standard GRIP system that reduces wheel slip by sending flow from the front wheel to the opposite rear wheel.

The system is designed to take on the most challenging course conditions ideal for undulating terrain, providing superior performance and traction out on the course.

The traction system in the A-models is driven by a servo-controlled hydrostatic pump. The control of the pump is no longer mechanical linkages, but instead it is electronic. The design reduced the complexity of the drive system meaning no more linkages to adjust or repair decreased routine maintenance and providing reliable day-in/day-out operation.

The end result is more options for mowing different terrain then just straight up and down. The standard GRIP system ensures that when mowing slopes on an angle the high side tire maintains tractions unlike like mechanical systems used on other rough mowers. This increases productivity in tight areas and reduces damage to turf from wheel slippage.

Forward/reverse pedals

Forward/reverse pedals

The operator will benefit from eHydro, too. The pedal effort has been reduced, reducing the foot fatigue during many hours of mowing.

No-tool notch adjustment system makes height-of-cut (HOC) changes a breeze

Deck HOC system

Deck HOC system

One common element among John Deere golf mowing products, reel or rotary, is that adjustments are quick and easy. The 9009A and 7400A TerrainCut™ Mowers are no different. All HOC adjustments can be performed without tools with an innovative notch system, similar to what is included on the Quick-Adjust 5 and Quick-Adjust 7 reel cutting units.

To adjust the HOC on the 9009A and 7400A TerrainCut, pull the levers at each end of the front and rear rollers outward. With the levers pulled out, give a quick tug to disengage the teeth in the notches. This allows the rollers to rotate upward and downward freely and easily.

Inside HOC indicator

Inside HOC indicator

Outside HOC indicator

Outside HOC indicator

Locate the HOC indicator on the inside of the adjuster arm and line up the tabs or use the top edge of the adjuster arm to line up the height on the gauge located on the outside. Re-engage the notches by rotating the levers back inward to lock the HOC into place. No tools are needed to complete the adjustment.

The adjustments must be performed on both the front and rear roller, and both rollers have the same adjustment process. A HOC label is also located on the rear of the deck to serve as a guide for setting the height of cut.

The HOC is adjustable 1.9 cm (3/4 in.) to 10.2 cm (4 in.), in 0.64-cm (1/4-in.) increments.

The HOC system has been redesigned from prior models to include a longer and stronger handle. Hardened notch material is used to improve durability and resistance to rust and debris.

Standard GRIP all-wheel drive traction system provides superior traction by reducing wheel slip

GRIP all-wheel drive traction valve and rear motors

GRIP all-wheel drive traction valve and rear motors

For superior traction with a true hydraulic four-wheel drive (4WD), the GRIP all-wheel drive traction system is standard equipment on the 8800A and 9009A TerrainCut™ Rough Mowers. This system reduces wheel slip by sending flow from the front wheel to the opposite rear wheel.

For example, if the front-right wheel starts to slip, hydraulic flow is diverted to the left-rear wheel to maintain positive traction. By allowing the flow to cross over to the opposite rear wheel, the system maintains traction not only while climbing straight up hills, but also on side-hills.

The GRIP all-wheel drive traction system is always engaged when driving forward with the 8800A and 9009A TerrainCut Rough Mowers. There are no electronics to engage the 4WD system, simplifying the electrical system and the design of the valve at the rear of the machine.

In reverse, a standard switch is provided that disengages 4WD. The switch senses the reverse pedal has been depressed and shuts off flow to the rear drive wheels. This ensures the front drive tires are doing the work in reverse rather than the rear tires, minimizing wheel slip and scuffing of turf when backing up an incline.

The end result is more options for mowing different terrain than just straight up and down. The GRIP system ensures that when mowing slopes on an angle, the high side tire maintains tractions unlike like mechanical systems used on other rough mowers. This increases productivity in tight areas and reduces damage to turf from wheel slippage.

LoadMatch™ electronic setting compensates speed of machine to keep power to the cutting units to maintain cut quality

LoadMatch setting

LoadMatch setting

LoadMatch is an electronic setting through the TechControl display that allows managers more control of the machine and how it is operated when out on the course.

Most operators will mow as fast as the mow setting will allow, keeping their traction pedal all the way down. However, in some conditions this can lead to poor cut quality.

One example is getting behind in mowing due to weather conditions. The grass is long and lush and to properly cut that amount of grass at one time, the operator should slow the traction speed. This allows the cutting units to maintain proper turning speed, process the grass, and properly cut in one pass. Not slowing down causes missed grass and an uneven appearance. This affects the after-cut appearance and also reduces productivity by having to mow a second time to properly cut the lush grass.

The LoadMatch feature compensates the traction speed of machine to keep power to the cutting units. In the long, lush conditions described above with LoadMatch engaged, the operator would still have the traction pedal all the way down, but the machine would sense the load and slow the traction speed to properly cut the mowing pass. Once the load is reduced, the machine will return to the normal mow speed.

LoadMatch puts the manager in control of cut quality instead of the operator.

AutoPedal™ feature lowers sound levels and fuel consumption during transport

AutoPedal

AutoPedal

The AutoPedal feature controls engine rpm and transport speed of the machine through the eHydro™ foot pedal controls. AutoPedal is similar to an automobile gas pedal operation; the more the forward pedal is pressed, the faster the machine moves and the higher the engine rpm; pressing the pedal less, the slower the machine moves and the lower the engine rpm.

On conventional machines, the engine rpm is controlled by the operator by means of a manual or electric/manual throttle. Operators are trained to always operate the engine at wide-open throttle. Running at wide open throttle means running the engine at its fastest speed, which increases the sound levels and fuel usage.

The AutoPedal system allows the engine to only run as fast as needed, meaning that as operators transport around the course, the engine speed is only as fast as needed for the transport speed. If the operator approaches play and stops, the engine rpm goes to idle. This makes transporting quieter and since the engine does not run full speed all the time, it reduces fuel consumption.

Once the operator reaches the mowing site, engages the mow switch on the CommandARM™ controls, the engine rpm automatically increases to full throttle for mowing.

Double-acting, single-rod hydraulic steering cylinder for lines in roughs as straight as fairways and greens

Steering cylinder and linkage system

Steering cylinder and linkage system

The 8800A and 9009A TerrainCut™ Rough Mower puts stripes on the roughs as straight as they are on the greens. Utilizing the same style steering cylinder as found on the 2500B PrecisionCut™ Mower, 2500E E-Cut™ Hybrid Riding Greens Mowers, PrecisionCut and E-Cut™Hybrid Fairway Mowers, the 8800A and 9009A TerrainCut Rough Mowers can mow the straightest lines of any rough mower in the industry today.

Traditional hydraulic cylinders have a rod on only one side of the cylinder. The cylinder on the 8800A and 9009A TerrainCut Rough Mower has one rod that goes through both sides of the cylinder. This equalizes volume and pressure on both sides of the cylinder packing, helping the operator make perfectly straight lines with little effort.

This system also equalizes the steering effort, meaning easy turns whether turning to the right or to the left.

The steering system is all about proven technology, not only with the cylinder itself, but also with the linkage system connecting the cylinder to the steering tires. The linkage system on the 8800A and 9009A TerrainCut Rough Mower has been used in John Deere Golf since 2008 and is common with the popular 5000 Series John Deere Utility Tractors, which already had proven reliability and durability with operators worldwide.

Low machine weight and tires sized for proper weight distribution, traction, and low ground pressure

Front tires

Front tires

Strong lightweight frame design

Strong lightweight frame design

The 9009A TerrainCut™ Rough Mower is the lowest weight at 27 in five-gang rough mower on the market. The lower weight helps reduce the overall foot print in fine turf conditions reducing compaction and turf stress. Along with the lower weight, the 9009A features 26.5 x12-12 turf tires for low footprint and maximum traction in the toughest conditions. This combination provides a strong traction package with low levels of ground compaction.