-

Menu -

Locations -

Search

John Deere 8000A E-Cut™ Hybrid Fairway Mower

Double tap to zoom

8000A E-Cut™ Hybrid Fairway Mower

Fairway Mowers

Overview:

- TechControl™ Display locks in performance, and uptime

- Final Tier 4 without sacrificing horsepower

- Proven hybrid design eliminates hydraulics from reel circuit

- Highly maneuverable, 3-wheel low PSI smooth tire configuration

Get A Quote

Fields with asterisks* are required. Please email our helpful staff with any questions or comments using the contact form.

Loan Calculator

Use the Loan Calculator to help you determine the financing and payment options that are best for you.

**The accuracy of this calculator and its applicability to your circumstances is not guaranteed. You should obtain personal advice from qualified professionals. This information is provided for illustrative purposes only and does not constitute an application. This notice does not guarantee loan approval, nor is it an offer or commitment to make a loan to you on the above terms.

Send To A Friend

Fields with asterisks* are required. Your friend will receive an email that contains a reference to this page. Please send this email only to people you know who would be interested in this information.

Share This Product:

Features

Three-wheel stance and smooth tires for excellent maneuverability and after-cut appearance

Smooth tires

Smooth tires

Three-wheel stance

Three-wheel stance

The 6080A, 6500A, and 6700A PrecisionCut™ and 6080A, 6500A, and 8000A E-Cut™ Hybrid Fairway Mowers help to make fairways that look like greens a reality.

An innovative, smooth tire design minimizes compaction and tire marking, especially in turns, giving a look similar to that from a riding greens mower. The GRIP all-wheel drive traction system works in combination with the smooth tire design to give a greens-quality appearance without sacrificing traction.

These machines also excel at weight distribution, ensuring each tire sees an equal amount of weight over a large tire surface area for a ground pressure that is friendly to the surface of the turf.

This three-wheel stance is common with riding greens mowers in the market today. This provides an after-cut appearance that is so good it looks like the fairways were mowed by a greens mower. The three-wheel stance also excels in maneuverability, allowing for tight turning at the end of passes for increased productivity.

Treaded tire

Treaded tire

For those who prefer to use a treaded tire rather than a smooth tire, a fairway tread is also available through Parts.

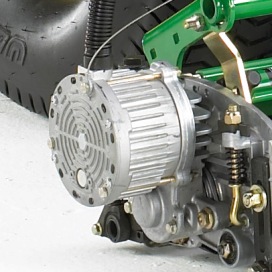

Electric reel drive system eliminates all potential leak points in the reel circuit

Electric motors drive cutting units

Electric motors drive cutting units

Ninety percent of all hydraulic leaks occur in the reel hydraulic circuit, mainly due to the necessity of having flexible hoses extending from the front of the machine for the front reels.

These hoses see a lot of flexing during the mowing day as cutting units are raised and lowered. Cutting units also steer and float to follow undulations, increasing fatigue for the reel motor hoses.

The 6080A, 6500A, 7500A, and 8000A E-Cut™ Hybrid Fairway Mowers have eliminated all reel circuit leak points by removing all hydraulics from the cutting unit drive circuit.

This has eliminated the following hydraulic components:

-

Reel drive section of hydraulic triple pump

-

Hydraulic reel motors

-

Backlapping valve

-

Flexible hoses

-

Fittings

-

Hard lines

Fewer hydraulic components leads to fewer leaks, increasing confidence that the finely manicured turf will not be damaged by hot hydraulic oil spilled onto a playing surface before an important tournament.

Reduced sound levels and fuel consumption at 2300 rpm

Reel circuit power source 180-amp alternator

Reel circuit power source 180-amp alternator

Electric motors drive cutting units

Electric motors drive cutting units

The E-Cut™ Hybrid Fairway Mowers are unique in that electrical power is used to minimize hydraulic leak opportunities in the reel circuit, but an engine is utilized to ensure optimal performance throughout the day. This presents an opportunity to further enhance machine performance through reduced sound levels and improved fuel savings, by running the machine at less-than-full throttle. When running the E-Cut Hybrid machines at the recommended reduced setting it does not sacrifice cut quality as the reel speed is still maintained at approximately 2200 rpm.

Mow engine speed screen

Mow engine speed screen

Password-protected settings

Password-protected settings

This reduced throttle setting is set quickly and easily using the TechControl display. Simply use the password-protected mower set-up screen Engine Mow Speed to set maximum engine speed while in mow. Once set, the engine speed automatically uses this rpm when the machine is mowing. This allows complete control of sound levels and fuel savings.

The 7500A and 8000A E-Cut™ Hybrid Fairway Mowers can be effectively run in mow at an engine rpm reduced to 2300 rpm. At this operating rpm, operators will experience noise reductions when compared to running the machines at full throttle.

In addition to the reduced sound levels, the operation at this engine rpm will reduce fuel usage due to slower engine rpm. Comparisons have shown that, depending on conditions and usage, fuel savings can be as high as 30 percent when running the machine at 2300 rpm as opposed to running at full throttle required by traditional hydraulic machines.

Brushless electric reel motors for compact design and optimal efficiency

Reel motors

Reel motors

The electric reel motors on the 6080A, 6500A, 7500A, and 8000A E-Cut™ Hybrid Fairway Mowers are brushless, allowing them to be compact in size, roughly equal to that of today's hydraulic reel motors. The brushless motors are very efficient, leading to years of optimal performance with very minimal maintenance, and sealed for protection from the elements.

The motors are bidirectional and variable speed, meaning they can spin forward or reverse and at a range of rotational speeds. The motors spin forward for mowing operations and backward for backlapping operations.

A poly-chain belt connects the motor shaft to the reel and rotates the reel when the cutting units are engaged. The internal components of the motor are sealed for long life, durability, and protection from the elements.

Cutting units are easily removed from the cutting unit motors by loosening the two bolts securing the motor to the cutting unit, turning the motor approximately a quarter turn, and pulling the motor from the cutting unit. This can be done in a matter of seconds. A tether prevents damage to the wiring harness when the motor is removed.

48-V, 180-amp alternator powers reel drive motors, requiring no additional batteries on unit

48-V 180-amp

48-V 180-amp

The reel circuit is powered by a 48-V, 180-amp alternator belt-driven by the engine. The alternator supplies constant power to the reel circuit and only generates 48 V when the mow system is engaged.

Due to this design, no additional batteries are required to drive the reel motors on the 6080A, 6500A, 7500A, and 8000A E-Cut™ Hybrid Fairway Mowers. With traditional electrical mowing systems, the frequency of clip would change as the batteries drained while mowing.

A battery pack begins to lose its power immediately when used, but not on the E-Cut Hybrids. Since they still use an engine to drive an alternator, the frequency of clip at the start of the day and at the end of the day is exactly the same, yielding unparalleled quality of cut from start to finish.

Plus, the machine doesn't have to be plugged in to charge the batteries once the day's mowing is done. The only limitation on run time with the E-Cut Hybrids is making sure the operator starts the day with a full fuel tank, just like with any other gas- or diesel-powered machine on the market today.

The alternator only supplies power to the reel circuit. The remainder of the circuits are powered by a 12-V battery.

TechControl display maximizes performance and uptime by allowing more control in operation and diagnostics

TechControl display

TechControl display

Password-protected settings

Password-protected settings

More control with the TechControl display with a large easy-to-read screen

Passcode-protected TechControl display enables quickly setting or changing mowing speed, turning speed, or transport speed to limit variations in performance by different operators.

Mow setting screen

Mow setting screen

Quickly adjust the mow or transport speed to make sure mow speed is what is needed for the changing conditions. The setting can be adjusted precisely using a speedometer app on a smartphone or global positioning system (GPS) device.

Turn-speed setting screen

Turn-speed setting screen

Use the TechControl to slow the machine during turns while mowing and protect against turf scuffing and aggressive turning operators.

The turn speed control engages when in mow and the cutting units are lifted for turns. Once the turn is made and the cutting units are lowered, the machine speed returns to the set mow speed.

The turn speed is a percentage of mow speed. When set to 100 percent, turn speed control is off or allows 100 percent of the mow speed in turns. Turn speed setting of 50 percent allows only 50 percent of the set mow speed to be reached during turns.

Here is an example:

Mow speed = 9.66 km/h (6 mph)

Turn speed set at 50 percent

Maximum turning speed will be 4.83 km/h (3 mph)

Input/output screen

Input/output screen

Service timers screen

Service timers screen

The A-model PrecisionCut™ Mowers, E-Cut™ Hybrid Mowers, and TerrainCut™ Mowers have the latest in advanced diagnostics through the TechControl display. Most all diagnostics are performed while sitting in the operator’s seat.

The TechControl has onboard visual diagnostics allowing quick and easy machine diagnostics, maximizing up time. The system allows technician to see inputs and outputs of the electrical system. Also, the technician can see stored controller codes on the machine to aide in troubleshooting incidents that may have occurred while on the course.

The TechControl will also display the notification for maintenance of the hydraulic and engine oils using service timers to notify when it has reached the time to perform the required service.

Language settings

Language settings

Choose from a list of several languages to use for the TechControl.

Operator warning notifications are incorporated into the TechControl and will alert the operator if a problem arises during operation.

Description |

Hydraulic over temp |

Hydraulic oil filter restriction |

Engine oil pressure low |

Engine coolant temperature |

Reel motor |

Battery voltage |

eHydro™ hydrostatic pump and large-capacity wheel motors for serious hill-climbing capabilities

Large wheel motors

Large wheel motors

eHydro™

eHydro™

The eHydro™ traction pump and wheel motors in the new A-model take performance, traction, and operation to the next level.

The new system was designed to take on the most challenging course conditions. The traction drive pump flow increased 35 percent and the wheel motors increase 17 percent in displacement over prior models. These increases to the traction system make the A-models ideal for undulating terrain providing superior performance and traction out on the course.

The new traction system in the A-models is driven by a servo-controlled hydrostatic pump. The control of the pump is no longer mechanical linkages, but instead is electronic.

Approximately 110 parts have been eliminated from the traction drive system compared to prior models. The new design also eliminated two adjustments. Reducing the complexity of the drive system means no more linkages to adjust or repair, decreased routine maintenance, and providing reliable day-in/day-out operation.

Forward/reverse pedals

Forward/reverse pedals

The operator will like the eHydro, too. The pedal effort has been reduced, thus reducing the foot fatigue during many hours of mowing.

AutoPedal™ feature lowers sound levels and fuel consumption during transport

AutoPedal

AutoPedal

The AutoPedal feature controls engine rpm and transport speed of the machine through the eHydro™ foot pedal controls. AutoPedal is similar to an automobile gas pedal operation; the more the forward pedal is pressed, the faster the machine moves and the higher the engine rpm; pressing the pedal less, the slower the machine moves and the lower the engine rpm.

On conventional machines, the engine rpm is controlled by the operator by means of a manual or electric/manual throttle. Operators are trained to always operate the engine at wide-open throttle. Running at wide open throttle means running the engine at its fastest speed, which increases the sound levels and fuel usage.

The AutoPedal system allows the engine to only run as fast as needed, meaning that as operators transport around the course, the engine speed is only as fast as needed for the transport speed. If the operator approaches play and stops, the engine rpm goes to idle. This makes transporting quieter and since the engine does not run full speed all the time, it reduces fuel consumption.

Once the operator reaches the mowing site, engages the mow switch on the CommandARM™ controls, the engine rpm automatically increases to full throttle for mowing.

GRIP all-wheel drive traction system moves flow from wheels that slip to those that grip

Rear-wheel motor

Rear-wheel motor

Hill-climbing power is essential with any golf course and this is one area where the 8000A E-Cut™ Hybrid truly excels. A powerful turbocharged diesel engine supplies power to the system. Combine that with a new larger eHydro™ and wheel motors the GRIP all-wheel drive traction system and the 8000A E-Cut Hybrid is one powerful hill-climbing machine .

The new traction drive includes an eHydro™ hydrostatic pump with 35 percent more flow and 17 percent more wheel torque than previous models to deliver the hill climbing performance expected with a fairway mower. The GRIP system transfers hydraulic flow from wheels that slip to wheels that grip. For example, if the right front wheel starts to slip, hydraulic flow goes to the left front and rear tires to maintain traction power.

The GRIP all-wheel drive traction system is standard equipment with the 8000A E-Cut Hybrid and it is also engaged at all times, in mow or in transport.

Double-acting, dual-rod hydraulic steering cylinder makes lines as straight as on greens, now on fairways

Steering cylinder end view

Steering cylinder end view

Ever wanted to mow fairways with the same quality straight lines mowed on greens? The double-acting, dual-rod hydraulic steering cylinder on the 8000A E-Cut™ Hybrid Fairway Mower does exactly that.

Using the same technology as incorporated on other PrecisionCut™, E-Cut Hybrid, and TerrainCut™ Mowers, the 8000A E-Cut Hybrid Fairway Mower produces high-quality straight lines through its unique steering system.

A rod on each side of the cylinder equalizes volume and pressure on each side of the cylinder, meaning equal steering effort from side to side. Once the cylinder is centered, it tracks as straight as an arrow. That means fairways and other areas can be mowed as straight as an arrow.

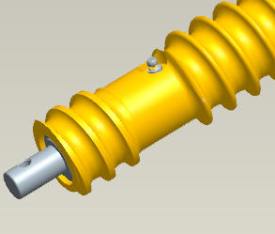

MTSpiral and MTGrooved roller options for most any turf condition

MTSpiral roller overall

MTSpiral roller overall

MTSpiral end section

MTSpiral end section

The MTSpiral roller and the MTGrooved roller (not shown) options are available for Quick-Adjust 5 (QA5) cutting units to minimize roller overlap marks.

The MTSpiral roller and the MTGrooved roller options take the patented 50.8-mm (2-in.) machine spiral roller to a whole new level. These designs reduce the number of times the grass is rolled in the overlap area of the cutting units. With these unique designs, the material in the overlap of the roller is machined down to a smaller diameter, allowing the ends of the rear cutting unit rollers to roll through the open space of the front cutting unit rollers.

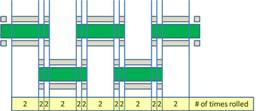

Types of overlap marks and what causes them

Cause of roller overlap marks

Cause of roller overlap marks

Roller overlap marks - bentgrass fairway

Roller overlap marks - bentgrass fairway

There are two types of overlap marks: reel overlap marks and roller overlap marks. It can often be difficult to determine what type of overlap marks a customer may be experiencing. In general, a roller overlap mark is roughly 88.9-mm (3.5-in.) to 101.6-mm (4-in.) wide, while a reel overlap tends to be 63.5-mm (2.5-in.) to 76.2-mm (3-in.) wide.

A reel overlap mark may be caused by a variety of factors:

- Bedknife attitude

- Low effective height of cut

- Frequency of clip to high (shorter distance between cuts)

- Cutting unit not parallel

- Bedknife to reel contact

- Dull reel and/or bedknife

- Turf stress

A roller overlap mark is caused by how many times the front and rear rollers of the cutting units go over the turf. With traditional roller setups, the grass is rolled four times in the overlap of the front and rear cutting units – once by the front roller of the front cutting unit, once by the rear roller of the front cutting unit, once by the front roller of the rear cutting unit, and once by the rear roller of the rear cutting unit.

The rest of the cutting unit roller surface, not in the overlap, rolls the grass twice, once by the front roller and once by the rear roller. In certain conditions, particularly in times of lush growth, this may result in overlap marks, which will be darker striping marks in the dark stripes and lighter striping marks in the light stripes.

How the MTSpiral roller and the MTGrooved roller minimize roller overlap marks

Overlap design of MTSpiral rollers

Overlap design of MTSpiral rollers

Reduction of overlap marks - bentgrass fairway

Reduction of overlap marks - bentgrass fairway

The MTSpiral roller and the MTGrooved roller change the game in terms of roller overlap marks. Due to their design, at no point is the grass rolled more than twice. At every point across all five cutting units, the grass is rolled exactly two times. What this means is a more uniform appearance across the cutting pass.

If a customer decides the MTSpiral roller or the MTGrooved roller is the right choice to meet the needs for their application, it is recommended that both front and rear rollers be replaced with the MTSpiral rollers, or MTGrooved rollers, to achieve optimum performance and minimize overlap marks.

Since these are spiral and grooved rollers, they will tend to engage the turf more than a cutting unit setup with a smooth rear roller. A starting guideline is that all cutting units equipped with front and rear MTSpiral rollers, or MTGrooved rollers, be set up with a benchsetting of at least 1.1 mm (0.05 in.) higher to achieve a similar effective height of cut. Proper height-of-cut setting is critical for this setup.

The optional MTSpiral roller or MTGrooved roller setup does not solve issues due to reel overlap marks. Height-of-cut when the MTSpiral roller or MTGrooved roller is used should be measured by placing the gauge bar approximately 101 mm (4 in.) from the end of the roller to stay away from the tapered ends.

Applications for the MTSpiral roller and the MTGrooved roller

Reduction of overlap marks - paspalum fairway

Reduction of overlap marks - paspalum fairway

MTSpiral rollers and MTGrooved rollers can be installed on all PrecisionCut™ and E-Cut™ Hybrid Fairway Mowers and Riding Greens Mowers with QA5 cutting units. They are an addition to the lineup of roller options for fairway, tee, and approach applications, and may help reduce roller overlap marks on both warm season and cool season turfgrasses. Use of the MTSpiral Rollers or MTGrooved rollers is not recommended for greens applications.

Available for both the 45.7-cm (18-in.) and 55.9-cm (22-in.) cutting units, the MTSpiral roller and MTGrooved roller feature a true 45.7-cm (18-in.) and 55.9-cm (22-in.) length with tapered ends. This full-length roller, as compared to other shorter rollers in the marketplace, supports the cutting unit in turns and on sidehills without the gouging or marking.

This design is only available in the 50.8-mm (2-in.) configuration at this time:

- BM23566 – 5.1-cm x 55.9- cm (2-in. x 22-in.) MTSpiral roller

- BM23567 – 5.1-cm x 45.7-cm (2-in. x 18-in.) MTSpiral roller

- BTC10267 - 5.1-cm x 55.9-cm (2-in. x 22-in.) MTGrooved roller

- BTC10281 - 5.1-cm x 45.7-cm (2-in. x 18-in.) MTGrooved roller

Cutting units are stable for easy transporting

Rubber-mounted front up stops

Rubber-mounted front up stops

Rear up stop

Rear up stop

The 6080A PrecisionCut™ and 6080A and 8000A E-Cut™ Hybrid Fairway Mowers have cutting units that contact up stops for transport. These up stops are rubber and limit cutting units from swinging during transport to protect the cutting units when transporting down cart paths or bumpy terrain.

Specifications

Key Specs

| Maximum rated horsepower | At 2800 rpm ISOC: 31 kW 41.6 hp |

|---|---|

| Drive pump | N/A due to Electric Driven Cutting units |

| Ground pressure | 69 kPa 10 psi |

| Throttle | Automatic controls with AutoPedal foot controls; manual control through TechControl display |

| Operator display | TechControl Display; Located on Command Arm; displays machine warnings, on-board electrical diagnostics; service timers on large easy to read screen; quick on the go settings for mow and transport speed; Turn Speed; Loadmatch™ and ON/OFF Cruise Control Use selection: all settings are pass code protected |

| Mowing speed | 12.8 km/h 8 mph |

| Cutting unit size | Quick Adjust QA5: 45.7 cm 18 in. |

| Total width of cut | 203 cm 80 in. |

| Reel diameter | 12.7 cm 5 in. |

| Frequency of clip (FOC Reels) OR Blade tip speed (decks) | 11 Blade: 0.69 mm/km/h 0.044 in./mph 7 blade: 1.09 mm/km/h 0.069 in./mph |

Engine

| Type | Direct Inject Turbocharged Diesel |

|---|---|

| Compliant emission regulation | United States and Canada Tier 4 |

| Horsepower | Maximum rated horsepower At 2800 rpm ISOC: 31 kW 41.6 hp |

| Cylinders | Three |

| Displacement | 1.568 L 95.69 cu in. |

| Air cleaner | 2-stage dry element |

| Fuel | Diesel Up to B20 compliant |

| Cooling system | Liquid centrifugal pump; forward machine location for optimum cooling |

Vehicle

| Traction drive | |

|---|---|

| Drive pump | N/A due to Electric Driven Cutting units |

| Cutting units drive | |

| Hydraulic system capacity | 37.8 L 10 U.S. gal. |

| Fuel tank capacity | 45.4 L 12 U.S. gal. |

| Steering | Hydraulic power with double acting steering cylinder |

| Front drive tires | 24x13x12 smooth |

| Steering tires | 24x13x12 smooth |

| Ground pressure | 69 kPa 10 psi |

| Brakes | Internal hydraulic wet disc brakes with dynamic braking through closed loop hydrostatic system |

| ROPS | Standard; meets ISO 21299 Standard |

Operating weight

| Cutting units lowered | 2131 lb 967 kg |

|---|

Controls

| Throttle | Automatic controls with AutoPedal foot controls; manual control through TechControl display |

|---|---|

| Forward/reverse | 2-pedal |

| Mower lift | One-touch single handle |

| Parking brake | Electric Switch on Command Arm for Internal Wet Disk Brakes |

| Seat | Suspension seat with seat belts and arm rest; fore/aft adjustment; weight and lumbar adjustment |

| PTO | Electric Switch on Command Arm |

| Ignition | |

| Work lights | |

| Tilt steering | Left Foot operated for easy adjustment |

| Operator display | TechControl Display; Located on Command Arm; displays machine warnings, on-board electrical diagnostics; service timers on large easy to read screen; quick on the go settings for mow and transport speed; Turn Speed; Loadmatch™ and ON/OFF Cruise Control Use selection: all settings are pass code protected |

| Storage | Cup holder; two-way radio; large operator storage located on left hand side of operator station |

Dimensions

| Height with ROPS | 210.8 cm 83 in. |

|---|---|

| Length | 292 cm 115 in. |

| Transport width | 89 in. 226 cm |

| Mowing position width | 236 cm 93 in. |

| Wheelbase | |

| Ground speed | Mowing 12.8 km/h 8 mph Transport 19.3 km/h 12 mph Reverse 9.6 km/h 6 mph |

Cutting Units

| Number | Five |

|---|---|

| Size | Quick Adjust QA5: 45.7 cm 18 in. |

| Total width of cut | 203 cm 80 in. |

| Height of cut | Construction Requires option bedknife for lowest HOC and 76.2 mm (3 in.) roller for highest: 2-28.5 mm 0.078-1.125 in. |

| Frequency of clip (FOC Reels) OR Blade tip speed (decks) | Rollers Front and rear: 51 in. 2 in. Optional: 76.2 mm 3 in. 11 Blade: 0.69 mm/km/h 0.044 in./mph 7 blade: 1.09 mm/km/h 0.069 in./mph |

| Reel diameter | 12.7 cm 5 in. |

| Bedknife adjustment | |

| Backlapping |

Sound levels

| Operator ear full engine | |

|---|---|

| Operator ear reduced engine rpm (2300 rpm) | |

| Measuring standard | ISO 11201 |

| Attachments installed | FTCs, reels engaged |

Fuel Economy

| Actual Fuel usage will vary depending on course conditions, operation, turf and fuel quality | 25% load: 2.8 L/hr 0.74 gph 40% load: 4.32 L/hr 1.14 gph 50% load: 5.22 L/hr 1.38 gph |

|---|

Warranty

| Type | Two-year limited |

|---|

Certification

| Type | ANSI B71.4-2012 |

|---|

Additional information

| Date collected |

|---|

Contact Us

-

325 Walt Messick Road

Harrington, Delaware 19952

Phone: (302) 398-3729

Toll Free: (800) 237-1272