Features

QA7 electric reel drive system meets customer needs for reduced hydraulic leaks, sound levels, and fuel consumption

56-Volt, 240 amp Smart alternator and electric reel motors provide power for mowing, verticutting, and scalping

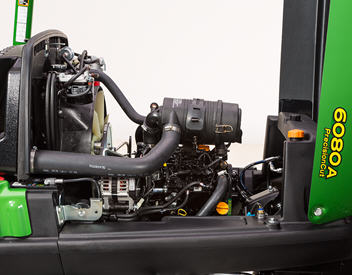

18.4-kW (24.7-hp) Final Tier 4 (FT4) diesel engine offers plenty of power for mowing

Three-wheel stance and smooth tires for excellent maneuverability and after-cut appearance

TechControl display maximizes performance and uptime by allowing more control in operation and diagnostics

GRIP all-wheel drive traction system moves flow from wheels that slip to those that grip

Specifications

Key Specs

| Maximum rated horsepower | At 3000 rpm: 24.7 hp (18.4 kW) High idle 3200 rpm |

|---|---|

| Drive pump | Axial piston, electronically controlled hydrostatic traction pump; dual gear pumps for steering, lift, mow, and charge |

| Ground pressure | 69 kPa 10 psi |

| Throttle | Hand throttle |

| Operator display | TechControl Display: Located on Command Arm; displays machine warnings, on-board electrical diagnostics; service timers on large easy to read screen; quick on the go settings for mow and transport speed; Turn Speed; Loadmatch™ and ON/OFF Cruise Control Use selection: all settings are pass code protected |

| Mowing speed | 0 to 12.8 km/h 0 to 8.0 mph |

| Cutting unit size | Quick Adjust QA5: 55.9 cm 22 in. |

| Total width of cut | 254 cm 100 in. |

| Reel diameter | 17.8 cm 7 in. |

| Frequency of clip (FOC Reels) OR Blade tip speed (decks) | 10- Blade: 1.04 mm/km/h 10- Blade: 0.066 in./mph 8-Blade: 1.30 mm/km/h 8-Blade: 0.083 in./mph |

Engine

| Type | Indirect Inject Diesel |

|---|---|

| Compliant emission regulation | United States and Canada Final Tier 4, EU Stage V |

| Horsepower | Maximum rated horsepower At 3000 rpm: 24.7 hp (18.4 kW) High idle 3200 rpm |

| Cylinders | Three |

| Displacement | 1.267 L 77.32 cu in. |

| Air cleaner | 2-stage dry element |

| Fuel | Diesel Up to B20 compliant |

| Cooling system | Liquid centrifugal pump; forward machine location for optimum cooling |

Vehicle

| Traction drive | |

|---|---|

| Drive pump | Axial piston, electronically controlled hydrostatic traction pump; dual gear pumps for steering, lift, mow, and charge |

| Cutting units drive | |

| Hydraulic system capacity | 37.8 L 10 U.S. gal. |

| Fuel tank capacity | 60.6 L 16 U.S. gal. |

| Steering | Hydraulic power with double acting steering cylinder |

| Front drive tires | 26.5x14-12 smooth |

| Steering tires | 24x13-12 smooth |

| Ground pressure | 69 kPa 10 psi |

| Brakes | Internal hydraulic wet disc brakes with dynamic braking through closed loop hydrostatic system |

| ROPS | Standard; meets ISO 21299 Standard |

Operating weight

| Cutting units lowered | 1181 kg 2598 lb Canopy, FTCs and Power Brushes installed, full fuel |

|---|

Controls

| Throttle | Hand throttle |

|---|---|

| Forward/reverse | 2-pedal electronic control of eHydro system |

| Mower lift | One-touch single handle |

| Parking brake | Electric Switch on Command Arm for Internal Wet Disk Brakes |

| Seat | Suspension seat with seat belts and arm rest; fore/aft adjustment; weight and lumbar adjustment |

| PTO | Electric Switch on Command Arm |

| Ignition | |

| Work lights | |

| Tilt steering | Left Foot operated for easy adjustment |

| Operator display | TechControl Display: Located on Command Arm; displays machine warnings, on-board electrical diagnostics; service timers on large easy to read screen; quick on the go settings for mow and transport speed; Turn Speed; Loadmatch™ and ON/OFF Cruise Control Use selection: all settings are pass code protected |

| Storage | Cup holder; two-way radio; large operator storage located on left hand side of operator station |

Dimensions

| Height with ROPS | 217.3 cm 85.6 in. |

|---|---|

| Length | 307.2 cm 121 in. |

| Transport width | 219 cm 86.2 in. |

| Mowing position width | 287 cm 113 in. |

| Wheelbase | |

| Ground speed | Mowing 0 to 12.8 km/h 0 to 8.0 mph 4WD mow speed N/A Transport 0 to 16.1 km/h 0 to 10.0 mph Reverse 0 to 9.7 km/h 0 to 6.0 mph |

Cutting Units

| Number | Five |

|---|---|

| Size | Quick Adjust QA5: 55.9 cm 22 in. |

| Total width of cut | 254 cm 100 in. |

| Height of cut | Construction 6.3 to 50.8 mm 0.25 to 2 in. |

| Frequency of clip (FOC Reels) OR Blade tip speed (decks) | Rollers Front and rear: 76.2 mm 3 in. at 1600 reel speed (engine high idle) - 10- Blade: 1.04 mm/km/h 10- Blade: 0.066 in./mph 8-Blade: 1.30 mm/km/h 8-Blade: 0.083 in./mph |

| Reel diameter | 17.8 cm 7 in. |

| Bedknife adjustment | |

| Backlapping |

Sound levels

| Operator ear full engine | |

|---|---|

| Operator ear reduced engine rpm (2300 rpm) | |

| Measuring standard | ISO 11201 |

| Attachments installed | FTCs, reels engaged |

Fuel Economy

| Actual Fuel usage will vary depending on course conditions, operation, turf and fuel quality |

|---|

Warranty

| Type | Two-year limited |

|---|

Certification

| Type | ANSI B71.4-2012 |

|---|

Additional information

| Date collected |

|---|