-

Menu -

Locations -

Search

John Deere 620R Loader

Double tap to zoom

620R Loader

Front End Loaders For Tractors

Overview:

- Automatic Mast Latch for fast implement changeover

- Repositioned leveling links for better visibility

- Designed for maximum tractor maneuverability

- Integrated stands for tool free attachment and removal

Get A Quote

Fields with asterisks* are required. Please email our helpful staff with any questions or comments using the contact form.

Loan Calculator

Use the Loan Calculator to help you determine the financing and payment options that are best for you.

**The accuracy of this calculator and its applicability to your circumstances is not guaranteed. You should obtain personal advice from qualified professionals. This information is provided for illustrative purposes only and does not constitute an application. This notice does not guarantee loan approval, nor is it an offer or commitment to make a loan to you on the above terms.

Send To A Friend

Fields with asterisks* are required. Your friend will receive an email that contains a reference to this page. Please send this email only to people you know who would be interested in this information.

Share This Product:

Features

Loader Technology package prep

Time and cost savings with Loader Technology package preparation

The loader technology package prep provides the installed harness and controller to further install a hardware bundle that has four key features to make material handling easier and more efficient. The package is only for mid-model year 2022 and newer 6R 110 to 6R 250 Tractors when equipped with the electric joystick and mid- valves.

Technology package hardware unlocks the following loader features when DWS option code is ordered with Loader Technology package prep.

Optional Loader Technology hardware if equipped (code 9661)

- Dynamic Weighing System (DWS)

- Level to Horizon (LTH)

- Return to Position (RTP)

- Electronic self-leveling (ESL)

Loader Technology when ordered with Loader Technology package prep (code 9661)

Return to Position (RTP), if equipped (code 9661)

This feature moves the loader boom and bucket automatically to easily preset positions. The operator can save boom upper height, lower height and 2 different bucket angles for both settings A and B. With a push, pull, left or right motion of the joystick just past a built in joystick detent to activate, then the loader automatically returns the boom and bucket to the preset position. This feature works great for an upper height to clear wagon and a lower bucket angle set for dumping then returning bucket back to zero, then lower loader back to a transport position. Re-zeroing implements is easy with a zero soft button on the RTP run page.

Mid-model year 2022 6R Tractor E-ICV joystick

Mid-model year 2022 6R Tractor E-ICV joystick

RTP can easily be switched off if manual operation is preferred.

Level to Horizon (LTH), if equipped (code 9661)

This feature levels the attachment parallel to the horizon, while conventional loader leveling systems maintain the same angle as the tractor. This means that when operating in hilly conditions, waterways, or in and out of buildings on the farm, the pallet fork, bucket, or other attachment is actively moved into a horizontal position. If this behavior is not desired by the operator, it can be turned off in the tractor display. The attachment is then leveled to the tractor if equipped with a leveling feature such as mechanical self-leveling (MSL). LTH is compatible with both self-leveling and non-self-leveling loaders

Dynamic Weighing System (DWS), if equipped (code 9661)

The DWS feature displays the current weight loaded on the attachment, such as a bucket, spear, or forks. The tractor does not need to stop for weighing, it’s constantly providing a weight reading allowing the operator to fill bucket to the required target weight without interrupting for a separate weighing cycle. Record weight with count as needed with a push of the joystick button.

It also allows the operator to create and save single material groups such as bales, feed, or fertilizer. Also, create and save a material group of up to 6 different materials. Display tracks single material group with section from material dropdown with record of count, minimum, maximum and average weight. The weighing system even registers multiple units. For example, in single material group you can count bales by 1, 2, or 3 with every loading cycle.

Operating the material group from the DWS run page by the selection of different stored material groups. Selecting the material is as easy as selecting one of listed materials and record the weight as you are loading. Weight will be recorded and count down to zero then a green checkmark will appear next to the material signifying that it has been completed, repeat until all materials have been added. A bar diagram and displayed values clearly show how much weight of the current component is still needed to achieve its target weight.

Loader camera option when ordered with Loader Technology package (code 9662)

Tractor showing the loader camera image

Tractor showing the loader camera image

The loader camera provides visibility to the loader carrier and surroundings. The hooks of the carrier are visible to facilitate connecting attachments. When working with pallet forks, the fork tips are visible to assist picking up pallets with ease. The video image is shown in the built-in display of the 6R Tractor.

DWS is a must for windy feed yards because you can weigh your lightweight commodities in the shed without blowing feed across your yard when feathering over feed wagon getting to a target weight.

Electronic self-leveling (ESL), if equipped (code 9661)

ESL maintains bucket positioning in any range of the boom. It can be easily activated and deactivated from the run pages. Toggling between ESL and LTH is as simple as selecting which leveling operation is needed through the run page on display. ESL is compatible with both self-leveling and non-self-leveling loaders. ESL is compatible with both self-leveling and non-self-leveling loaders.

Benefits

- Faster and easier loading of goods with RTP

- No manual controlling of heights and angles to avoid trailers, sheds, etc.

- Weighing on the go without the time-consuming needing to stop and perform a weighing cycle

- No time lost returning excessive load from mixer wagons

- No effort to rewrite the target weight of all individual components when changing silage pits with a different nutrition value or varying herd size

- No need to purchase a feeder wagon scale

- Fast filling of target weight in the bucket without interrupting to verify the current weight

- Less risk of loss of expensive commodities caused by the wind blowing over wagon

Automatic bale counter versus paper notes in the cab - Can weigh liquids and even partial loads on pallets or in containers and buckets

- Avoid spilling goods or transport multiple bales without dropping them with the LTH feature

The camera is factory-installed in the loader factory; the wiring harness is protected inside the boom. The camera angle can be adjusted if needed. It is possible that a different position of the camera is desired, such as showing the contents of a bucket or the side of a snow blade. For such unique desires, spare cable length is available to enable customized camera positions.

Benefits

- Fast connection of attachments

- No damage to pallets and goods loaded on forks and spears

- Possibility for customized camera position

Single-point hydraulic connection to save time

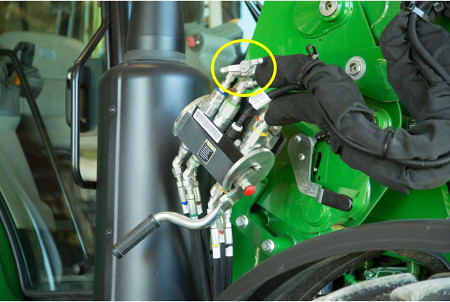

Single-point hydraulic connection on the 600R Loader

Single-point hydraulic connection on the 600R Loader

The R-Series Loaders feature a single-point hydraulic connection that saves the operator time when attaching or detaching the loader. This feature also incorporates the connection point for any electrical needs as well as the hydraulic lockout valve. With all hydraulic and electrical connections in one location, installation is quickly completed with the pull of a handle.

NOTE: Before disconnecting the hydraulic connection between the loader and the tractor, it is necessary to release the hydraulic pressure.

Single-point hydraulic connection (open)

Single-point hydraulic connection (open)

Single-point hydraulic connection (closed)

Single-point hydraulic connection (closed)

Improve appearance and reduce damage with concealed oil lines

600R Loader with concealed oil lines

600R Loader with concealed oil lines

The R-Series Loaders are designed to route the oil lines and hydraulic lines through the boom arm and the torque tube. This internal routing ensures better protection of the lines from external damage and improves the overall appearance of the loader.

600R Loader (side view)

600R Loader (side view)

600R Loader (angle view)

600R Loader (angle view)

Easy loader removal and installation using Mast Latching System

New Mast Latch System for the 5R and 6R series loaders makes it easy to attach and detach the loader from the tractor. The system provides easy visual references from both the inside and outside of tractor cab. This feature provides a large pin that is inserted through the mast just above the latching mechanism, providing a quick visual reference from the operator station and during walk around inspections. This pin is attached to the loader with a cable with a convenient storage bracket when the loader is removed. When the loader is attached, the pin provides a sliding handle to assist with alignment and keeping the loader securely attached.

Mast Latch System pin installed in locked position

Mast Latch System pin installed in locked position

Mast Latch System pin in stored position

Mast Latch System pin in stored position

The inside of the loader mast has a new sticker that is easy to see from cab. This offers an indicator for when latched, to rest over the checkmark and provides a lock symbol just above the pin protrusion. The Mast Latch System is a pin and mechanical lever that allows operators to remove or attach the loader with one trip out of the cab.

Inside of mast shown from operator station

Inside of mast shown from operator station

Easy service with boom lockout

Hydraulic shut-off valve on R-Series Loader

Hydraulic shut-off valve on R-Series Loader

The R-Series Loaders come equipped with a hydraulic shut-off valve to improve serviceability. When conducting brief service to the loader, close the hydraulic shut-off valve to ensure the loader does not move while operating under the equipment. This feature promotes a safe way to conduct brief maintenance without having to use support stands or removing the loader completely.

Faster cycle time for mechanical self-leveling (MSL) loaders using false rod cylinders -

600R Loader working with 6120M Tractor

600R Loader working with 6120M Tractor

The MSL R-Series Loaders utilize a false rod cylinder to improve bucket performance. This bucket cylinder is designed with a smaller displacement of oil required on the head end of the cylinder, which allows the cylinder to function more quickly, decreasing operation cycle time. With the false rod cylinder design, loader applications can work more quickly and efficiently.

False rod cylinders on 600R Loader

False rod cylinders on 600R Loader

Specifications

Key Specs

| Maximum lift height (A) | 4131 mm 163 in. |

|---|---|

| Lift capacity at full height | Measured at pivot (U) 2348 kg 5176 lb |

| Boom breakout force | Measured at pivot (Y) 3006 kgf 6627 lbf |

| Bucket rollback force capacity | At ground-level line (ZZ) 4238 kgf 9343 lbf |

| Clearance at full height - bucket dumped (C) | 3123 mm 123 in. |

| Dump angle, degrees (E) | -59 degree (angle) |

| Rollback angle, degrees (G) | 48 degree (angle) |

Tractor

| Model | 6105R/M, 6115R/M, 6125R/M |

|---|---|

| Front tire | 480/70R24 |

| Rear tire | 520/70R38 |

| Front axle configuration | MFWD with Limited Slip Differential |

| Wheelbase | 2580 mm 102 in. |

| Pump capacity | 114 L/min 30.1 gpm |

| Rated pressure | 200 bar 2901 psi |

Loader

| Base weight | 1498.4 kg |

|---|---|

| Leveling configuration | Mechanical Self Leveling (MSL) |

| Bucket used | 2150HD Grapple |

| Bucket weight | 372 kg 821 lb |

| Lift capacity at full height | Measured at pivot (U) 2348 kg 5176 lb Measured at 800 mm ahead of pivot (V) 2189 kg 4829 lb |

| Lift capacity at 59 in. (1500 mm) | Measured at pivot (W) 2686 kg 5922 lb Measured at 800 mm ahead of pivot (X) 2531 kg 5580 lb |

| Boom breakout force | Measured at pivot (Y) 3006 kgf 6627 lbf Measured at 800 mm ahead of pivot (Z) 2546 kgf 5613 lbf |

| Bucket rollback force capacity | At maximum height (VV) 2433 kgf 5364 lbf At 59-in. (1500-mm) lift height (XX) 4301 kgf 9482 lbf At ground-level line (ZZ) 4238 kgf 9343 lbf |

| Dimensions | Maximum lift height (A) 4131 mm 163 in. At full height - bucket level(B) 3891 mm 153 in. At full height - bucket dumped (C) 3123 mm 123 in. |

| Overall length (I+F), ft (m) | 4.9 m 16.2 ft |

| Overall height in carry position (J) | |

| Digging depth (H) | 53 mm 2 in. |

| Reach | At maximum height (D) 819 mm 32 in. At ground level - bucket level (F) 2504 mm 99 in. |

| Bucket angle | Dump angle, degrees (E) -59 degree (angle) Rollback angle, degrees (G) 48 degree (angle) Dump angle, ground -99 degree (angle) |

| Cycle times | Loader raise, seconds 3.37 seconds Loader lower, seconds 2.53 seconds Bucket dump, seconds 1.81 seconds Bucket rollback, seconds 1.81 seconds |

Additional information

| Date collected |

|---|

Contact Us

-

325 Walt Messick Road

Harrington, Delaware 19952

Phone: (302) 398-3729

Toll Free: (800) 237-1272