-

Menu -

Locations -

Search

John Deere 316GR Skid Steer

316GR Skid Steer

Skid Steers

Overview:

- Gross Power: 48.5 kW (65 hp)

- Net Power: 45.6 kW (61 hp)

- Rated Operating Capacity: 795 kg (1,750 lb.)

- Operating Weight: 2806 kg (6,180 lb.)

Get A Quote

Fields with asterisks* are required. Please email our helpful staff with any questions or comments using the contact form.

Loan Calculator

Use the Loan Calculator to help you determine the financing and payment options that are best for you.

**The accuracy of this calculator and its applicability to your circumstances is not guaranteed. You should obtain personal advice from qualified professionals. This information is provided for illustrative purposes only and does not constitute an application. This notice does not guarantee loan approval, nor is it an offer or commitment to make a loan to you on the above terms.

Send To A Friend

Fields with asterisks* are required. Your friend will receive an email that contains a reference to this page. Please send this email only to people you know who would be interested in this information.

Share This Product:

Features

Increase your machine’s versatility with John Deere’s wide array of attachment offerings

John Deere 316GR equipped with an auger

John Deere 316GR equipped with an auger

John Deere 316GR equipped with bale spear

John Deere 316GR equipped with bale spear

John Deere 317G equipped with pallet forks

John Deere 317G equipped with pallet forks

John Deere 318G equipped with a rock grapple

John Deere 318G equipped with a rock grapple

With over 100 attachments offered in the John Deere portfolio you can make the most out of your skid steer by equipping it with several popular attachments.

- Increased auxiliary hydraulic flows and power over previous models enable greater performance while running attachments

- Optional electrically actuated Quik-TatchTM enables some attachment connecting to take place within the cab reducing the need for exiting and re-entering the cab to manually connect attachments.

- Creep control (offered within the Joystick Performance Package) allows operators to perform precise tasks that require full hydraulic flow and power while running at lower travel speeds

- Vertical lift configuration on the 317G and 318G allows for higher attachment reach and increased stability

For additional information on attachments and compatibility, check out the John Deere attachments guide.

Enjoy all day comfort and operational ease with the spacious, updated cab

The updated G-Series cab complete with a lap bar

The updated G-Series cab complete with a lap bar

Optional ISO-H switchable controls on the sealed switch module (SSM)

Optional ISO-H switchable controls on the sealed switch module (SSM)

To maximize productivity and comfort, an array of enhancements have been made to the cab and controls to keep operators satisfied throughout the entire day.

- 25 percent more cab volume than the E-Series including the addition of a lap bar

- The sealed and pressurized cab reduces outside noise and keeps the dust out

- Optional air ride heated seat provides customers working throughout the cold winter months increased comfort

- Optional Bluetooth radio enables streaming of content from a cell phone.

- Optional International Organization for Standardization (ISO)-H switchable controls with electrohydraulic (EH) Joystick Performance Package allows operators to easily select the pattern they prefer

- Differential steering allows the operator to maintain speed and traction when pushing through a turn

Increase Productivity with Electrohydraulic (EH) Controls

Left-hand EH joystick

Left-hand EH joystick

Right-hand EH joystick

Right-hand EH joystick

Full view of operator station

Full view of operator station

Overview

Electrohydraulic (EH) controls offer increased functionality to allow operators to customize machine operations based on preference. The EH controls also require less operator effort and are not as fatiguing over longer periods of operation compared to manual linkages. With fewer physical components and maintenance requirements, EH control machines provide operators with increased productivity across a variety of job applications.

Benefits

- EH tracking is adjusted electronically from the monitor and can be tuned while machine is in operation

- Joysticks provide low effort fingertip operations and can be modified for each control style or application

- Anti-stall engine software prevents operator from unintentionally stalling the engine under heavy loads

- True Auto-Idle automatically idles engine when static for 5 seconds to save on fuel and component wear

- EH machines offer differential steering, an exclusive John Deere feature that speeds up the outside turning of tires/tracks for faster jobsite maneuvering

- EH control transition unlocks design improvements to reduce cab noise, significantly lower vibration, and offer better cab sealing, pressurization, and heating, ventilation, and air conditioning (HVAC) performance

Maneuverability of small frame machines allows for quality performance in tight spaces

316GR skid steer with radial lift

316GR skid steer with radial lift

318G maneuvering within a small area

318G maneuvering within a small area

Small frame G-Series machines accomplish heavy work in smaller spaces without sacrificing performance.

- Multiple tire and track options enable G-Series machines to slim down and fit through narrow openings

- 316GR and 318G have a width below 1600.2 mm (63 in.)

- Two-pin attachment on the 316GR radial lift means fewer pivot points and less side-to-side movement

- Clear sightline to the cutting edge and bucket corners instills confidence when working in close quarters

Added mobility features allow for easier transport on and between job sites

317G transport behind a standard pickup

317G transport behind a standard pickup

Integrated front tie-down on boom

Integrated front tie-down on boom

Integrated rear tie-down

Integrated rear tie-down

The size and design of small frame G-Series machines makes them easy to transport which provides owners and operators with a machine containing many features of larger machines but with a more compact footprint.

- Integrated and easily accessible tie-downs in the front and rear of machines ensure safe and secure transport between job sites and allow for faster securing without the need to crawl under or over the machine

- Operating weight between 2441.7 kg - 3143.8 kg (6542 lb - 8423 lb) enables lightweight trailer transport behind a standard pickup truck

- Two-speed power train option on the 316GR and 318G delivers travel speeds up to 16.3 km/h (10.1 mph) allowing operators to move from one side of the job site to the other much faster

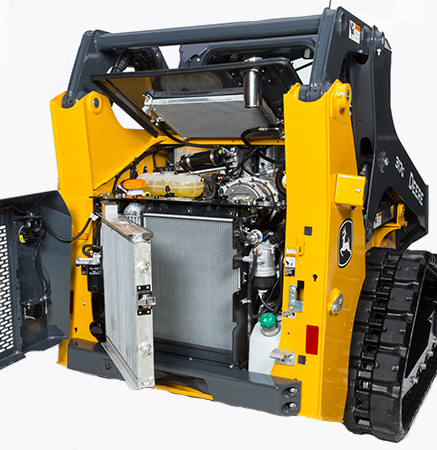

Ease of serviceability allows you to spend more time completing the tasks at hand

Small-Frame Skid Steer

Small-Frame Skid Steer

Swing-out rear door and hydraulic cooler

Swing-out rear door and hydraulic cooler

Enhanced serviceability features and ease of access to daily and preventative maintenance points ensures that these tasks do not significantly cut into working hours

- Swing-out rear door enables easy access to daily service checkpoints and cooling system

- The hood tilts up for ground level access to the dipstick, fuel and fluid filler necks, filters, and see-through reservoirs

- A single person can lock the boom and swing the operator’s station up in less than two minutes for easy drivetrain reach.

- Redesigned Quik-Tatch™ system optimized for effortless reach to grease zerks

- Optional JDLink™ provides machine data and health alerts to help decrease costly downtime

Excellent visibility for increased situational and jobsite awareness

Deluxe lighting package with light-emitting diode (LED) side-lighting

Deluxe lighting package with light-emitting diode (LED) side-lighting

Low-sloped rear hood

Low-sloped rear hood

Rearview camera attachment

Rearview camera attachment

Removable glass windows from inside the cab

Removable glass windows from inside the cab

Enhanced visibility features increase jobsite awareness and allow operators to be as precise and productive as possible.

- Optional deluxe lighting package with light-emitting diode (LED) lamps and side lights provides increased visibility early in the morning or at night over the standard halogen package

- Clear sight from the seat to the tires when boom arms are raised, and great visibility to the cutting edges and Quik-TatchTM lock indicators when boom is lowered

- Rear view camera, low-sloped hood, and a high cross-tube on the upper-linkage result in unmatched rear visibility

- Removable glass windows from inside the cab ensure that windows can be easily and adequately cleaned to improve visibility

Specifications

DESCRIPTION

| Lift Geometry | Radial |

|---|

DRIVELINE

| Engine Manufacturer | Yanmar |

|---|---|

| Engine Model | 4TNV86CHT |

| Aspiration | Turbocharger |

| Displacement, ltr (Inches³) | 2.1 (128) |

| Rated Speed, rpm | 2600 |

| SAE Net Power, kW (hp) | 45.6 (61) |

| SAE Gross Power, kW (hp) | 48.5 (65) |

| Max. Gross Torque, Nm (lbf / ft) | 207 (153) |

| Tire size - Standard | 10 - 16.5 |

DIMENSIONS

| Length - No Bucket, mm (inches) | 2630 (103) |

|---|---|

| Length - With Bucket Foundry, mm (inches) | 3240 (127.6) |

| Width - No Bucket, mm (inches) | 1600 (62.9) |

| Overall Height, mm (inches) | 1960 (77.2) |

| Ground Clearance, mm (inches) | 180 (7) |

| Wheelbase, mm (inches) | 1050 (41.5) |

| Rear Departure Angle, Degrees | 22.3 |

| Height to Hinge Pin, mm (inches) | 2920 (115.1) |

| Dump Angle, Degrees | 45 |

| Dump Height - Maximum Foundry, mm (inches) | 2250 (88.6) |

| Reach - Max Dump Height Foundry, mm (inches) | 400 (15.8) |

| Rollback - Ground Level, Degrees | 30 |

CAPACITIES

| Fuel Tank, ltr (gallons (US)) | 71 (19) |

|---|

PERFORMANCE

| Rated Operating Capacity - Foundry, kg (lbs) | 795 (1750) |

|---|---|

| Tipping Load - Foundry, kg (lbs) | 1589 (3500) |

| Speed - Maximum, kph (mph) | 11.1 (6.9) |

| Breakout - Lift Foundry, kN (lbf) | 21.1 (4750) |

| Breakout - Bucket Foundry, kN (lbf) | 23.3 (5250) |

| Hydraulic Power, kW (hp) | 24.729 (33.1) |

| Pump Output, lt/min (gallons (US) / min) | 63 (17) |

| System Pressure, bar (PSI) | 237.87 (3450) |

WEIGHTS

| Operating Weight - Foundry, kg (lbs) | 2806 (6180) |

|---|

Contact Us

-

325 Walt Messick Road

Harrington, Delaware 19952

Phone: (302) 398-3729

Toll Free: (800) 237-1272